Featured Services

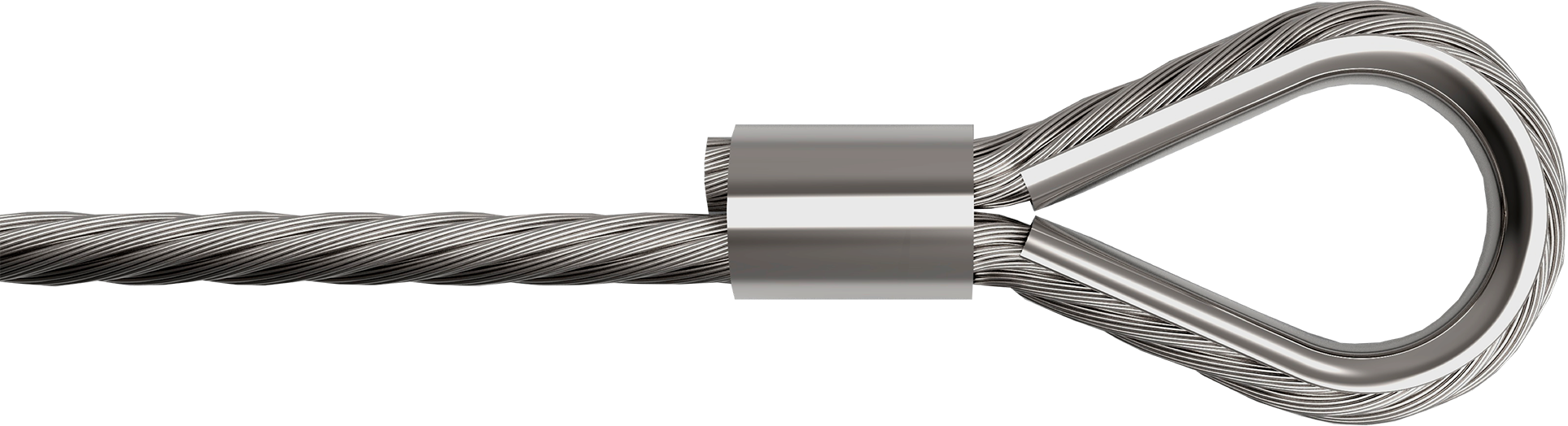

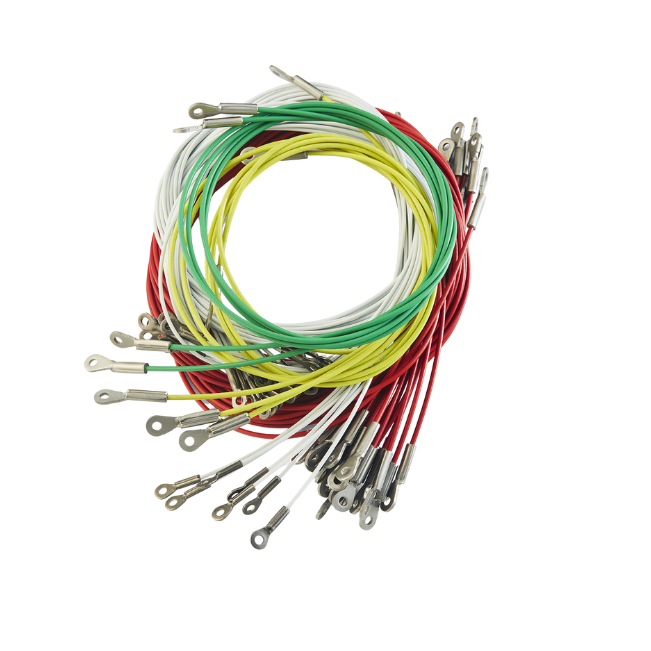

Tyler Madison’s services are expertly crafted custom cable assemblies and controls, known for their precision, durability, and innovation.

Industries Served

Tyler Madison’s wire rope and steel cable assemblies have thousands of different applications and uses. We carry a large inventory of standard and stock rope assemblies, but excel in custom cable assemblies and cable end fittings. No matter what your application or industry, contact Tyler Madison first for a quick solution to your needs.

- Aircraft

- Appliances

- Architectural

- Automotive

- Boating

- Construction

- Electronic

- Entertainment/Music

- Fitness

- Furniture

- Farm Equipment

- Industrial

- Lawn & Garden

- Lightning

- Machinery

- Material Handling

- Medical

- Recreational Vehicles

- Security

- Sporting Goods

- Toys

- Windows

Request a Quote

Submit your info and basic project details and our qualified staff will contact you promptly to discuss your inquiry.

- Contact us by filling out the form

- We will be in touch to review & confirm

- Receive order

Contact Us

Ready to take the next step? Contact Tyler Madison for expert advice and custom cable solutions. Our team is eager to assist with any questions and to help you achieve your project goals with precision and care. Let’s work together to create something exceptional.

Prefer to speak directly? Give us a call, and our team will be happy to assist you right away.